Premium Manufacturing Components

CR Injectors

ELKOSO proudly offers a comprehensive range of OEM injectors and pumps, tailored to meet the diverse needs of our

clients across various vehicles. Whether for automotive, marine, or agricultural applications, ELKOSO’s OEM products can support every market.

clients across various vehicles. Whether for automotive, marine, or agricultural applications, ELKOSO’s OEM products can support every market.

ELKOSO proudly offers a comprehensive range of OEM injectors and pumps, tailored to meet the diverse needs of our clients across various vehicles.

Technical Info

Additional Info

Technical Info

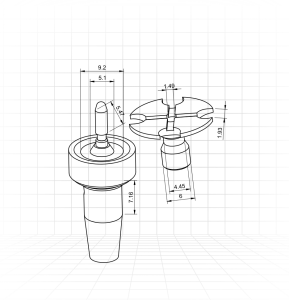

CR Injectors

Technical Specifications

- Injector Components:

- Injector Body: Houses all the internal components and is designed to withstand high pressures.

- Nozzle: Features precision-drilled holes to atomize fuel into the combustion chamber.

- Valve Assembly: Controls the timing and amount of fuel injection.

- Control Solenoid: An electromagnetic device that precisely controls the injector needle based on signals from the engine control unit (ECU).

- Dimensions and Tolerances:

- Orifice Diameter: Nozzle orifice diameters typically range from 100 to 200 micrometers, with tolerances in the range of a few micrometers.

- Critical Dimensions: Components such as the needle and valve require precise geometries to ensure proper sealing and fuel delivery.

- Performance Requirements:

- Pressure Handling: Injectors must withstand pressures up to 2,500 bar (36,000 psi) or higher.

- Durability: Components must resist wear and fatigue under high-pressure cyclic loads.

- Precision Fuel Delivery: The injector must provide precise fuel atomization and metering to ensure efficient combustion and compliance with emissions standards.

Quality Control and Testing

- Non-Destructive Testing (NDT):

- X-Ray Inspection: Used to detect internal flaws or inconsistencies in the material.

- Magnetic Particle Inspection: Identifies surface and near-surface defects.

- Dimensional Inspection:

- Coordinate Measuring Machines (CMM): Used for high-precision measurement of injector components.

- Surface Roughness Testing: Ensures the surface finish meets the required specifications for optimal performance.

- Performance Testing:

- Spray Pattern Analysis: Ensures the injector produces the correct spray pattern for optimal fuel-air mixing.

- Flow Rate Testing: Verifies that the injector delivers the correct amount of fuel.

- Durability Testing: Simulates long-term operation to ensure the injector can withstand prolonged use without failure.

By utilizing high-quality materials, advanced manufacturing processes, and rigorous quality control, ELKOSO ensures that its complete common rail injectors and their spare parts meet the demanding requirements of modern diesel engines, providing reliable and efficient fuel injection to optimize performance and minimize emissions.

Additional Info