Premium Manufacturing Components

Βαλβίδες έγχυσης CR

Elkoso, with years of unwavering commitment to precision engineering and innovation,

stands as a prominent industry leader in the production of high-quality valves for common rail injectors.

Our seasoned expertise in this field has allowed us to develop cutting-edge solutions that set new standards for efficiency and reliability.

With a keen focus on the intricate requirements of common rail systems, Elkoso’s valves are meticulously crafted using state-of-the-art manufacturing processes.

Our skilled team, backed by years of experience, ensures that each valve meets stringent quality standards, providing optimal performance and durability.

As a trusted name in the industry, Elkoso continues to play a pivotal role in advancing common rail injector technology,

offering solutions that empower diesel engines with enhanced fuel efficiency, reduced emissions, and unparalleled reliability.

stands as a prominent industry leader in the production of high-quality valves for common rail injectors.

Our seasoned expertise in this field has allowed us to develop cutting-edge solutions that set new standards for efficiency and reliability.

With a keen focus on the intricate requirements of common rail systems, Elkoso’s valves are meticulously crafted using state-of-the-art manufacturing processes.

Our skilled team, backed by years of experience, ensures that each valve meets stringent quality standards, providing optimal performance and durability.

As a trusted name in the industry, Elkoso continues to play a pivotal role in advancing common rail injector technology,

offering solutions that empower diesel engines with enhanced fuel efficiency, reduced emissions, and unparalleled reliability.

Producing complete common rail injectors, along with their spare parts, is a complex and precision-driven process. ELKOSO, as a manufacturer, focuses on high precision, durability, and efficiency to meet the demanding requirements of modern diesel engines. Below is detailed technical information regarding the production of complete common rail injectors by ELKOSO.

Technical Info

Additional Info

Technical Info

Βαλβίδες έγχυσης CR

Technical Specifications

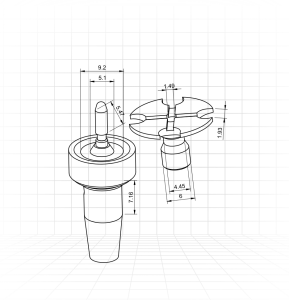

- Dimensions and Tolerances:

- Valve Geometry: The specific design and dimensions depend on the engine and injector system, but typical valve components include the needle, seat, and body with tolerances in the range of micrometers.

- Critical Dimensions: Orifice diameters, seat angles, and needle profiles must be precisely controlled to ensure proper fuel delivery and atomization.

- Performance Requirements:

- Pressure Handling: Valves must withstand injection pressures up to 2,500 bar (36,000 psi) or higher.

- Durability: Materials and coatings must provide long-term resistance to wear and fatigue under high-pressure cyclic loads.

- Seal Integrity: The valve must maintain a perfect seal to prevent leaks and ensure precise fuel metering.

Quality Control and Testing

- Non-Destructive Testing (NDT):

- Ultrasonic Testing: Detects internal flaws or inconsistencies in the material.

- Magnetic Particle Inspection: Identifies surface and near-surface defects.

- Dimensional Inspection:

- Coordinate Measuring Machines (CMM): Used for high-precision measurement of valve components.

- Surface Roughness Testing: Ensures the surface finish meets the required specifications for optimal performance.

- Performance Testing:

- Leak Testing: Ensures the valve maintains seal integrity under high pressures.

- Flow Rate Testing: Verifies that the valve allows the correct amount of fuel to pass through.

- Durability Testing: Simulates long-term operation to ensure the valve can withstand prolonged use without failure.

By combining high-quality materials, advanced manufacturing processes, and rigorous quality control, ELKOSO ensures that its common rail injector valves meet the demanding requirements of modern diesel engines, providing reliable and efficient fuel injection to optimize performance and minimize emissions.

Additional Info