Premium Manufacturing Components

Celdas de batería híbridas

At the heart of our company’s commitment to sustainable mobility lies our expertise in manufacturing cutting-edge battery cells tailored for hybrid cars.

With a keen focus on environmental responsibility and technological excellence, we take pride in producing high-performance battery solutions

that power the next generation of hybrid vehicles.

Our state-of-the-art manufacturing facility employs advanced processes and quality control measures

to ensure the seamless integration of our battery cells into hybrid powertrains.

By prioritizing energy efficiency, reliability, and longevity, our batteries contribute to enhancing the overall performance of hybrid cars,

maximizing fuel efficiency, and reducing emissions.

As a pioneering force in the green transportation revolution, our company is dedicated to driving innovation in the field of hybrid vehicle battery technology,

paving the way for a cleaner and more sustainable automotive future.

With a keen focus on environmental responsibility and technological excellence, we take pride in producing high-performance battery solutions

that power the next generation of hybrid vehicles.

Our state-of-the-art manufacturing facility employs advanced processes and quality control measures

to ensure the seamless integration of our battery cells into hybrid powertrains.

By prioritizing energy efficiency, reliability, and longevity, our batteries contribute to enhancing the overall performance of hybrid cars,

maximizing fuel efficiency, and reducing emissions.

As a pioneering force in the green transportation revolution, our company is dedicated to driving innovation in the field of hybrid vehicle battery technology,

paving the way for a cleaner and more sustainable automotive future.

At the heart of our company’s commitment to sustainable mobility lies our expertise in manufacturing cutting-edge battery cells tailored for hybrid cars. With a keen focus on environmental responsibility and technological excellence.

Technical Info

Additional Info

Technical Info

Celdas de batería híbridas

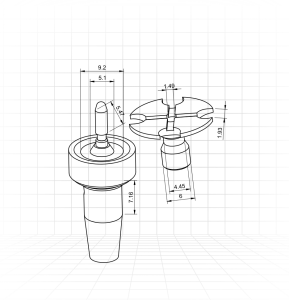

Technical Specifications

- Cell Types:

- Prismatic Cells: Rectangular cells offering high energy density and efficient space utilization, commonly used in automotive applications.

- Cylindrical Cells: Known for robust mechanical stability and ease of manufacturing, used in various applications.

- Pouch Cells: Flexible and lightweight design allowing for custom shapes and sizes, offering high energy density.

Quality Control and Testing

- Non-Destructive Testing (NDT):

- X-Ray Inspection: Detects internal defects and ensures proper alignment of electrodes.

- Ultrasonic Testing: Identifies delamination and other internal faults.

- Electrochemical Testing:

- Capacity Testing: Measures the charge and discharge capacity to ensure cells meet specified energy storage requirements.

- Impedance Testing: Evaluates the internal resistance to identify potential performance issues.

- Environmental Testing:

- Thermal Testing: Ensures cells can operate safely over a wide temperature range, typically from -20°C to 60°C.

- Vibration and Shock Testing: Simulates real-world conditions to ensure mechanical robustness.

- Performance Testing:

- Cycle Life Testing: Conducts repeated charge and discharge cycles to assess longevity.

- Safety Testing: Includes overcharge, short-circuit, and thermal runaway tests to ensure cell safety under extreme conditions.

By leveraging advanced materials, precision manufacturing processes, and rigorous quality control, ELKOSO ensures that its battery cells for hybrid cars meet the demanding requirements of modern hybrid vehicles, providing reliable performance, safety, and longevity.

Additional Info