At Elkoso, precision manufacturing is at the core of our commitment to excellence,

and this is particularly evident in our production of nozzles and nuts for common rail injectors.

With an extensive history in the industry, we have honed our expertise to deliver components that exemplify accuracy and reliability.

Our state-of-the-art manufacturing facility employs cutting-edge technology and meticulous quality control

measures to ensure that each nozzle and nut meets the exacting specifications required for common rail systems.

The precision engineering carried out by our skilled team guarantees the seamless integration of these components,

contributing to the overall efficiency and performance of common rail injectors.

Elkoso’s dedication to precision manufacturing is not just a commitment; it’s a testament to our unwavering pursuit of providing clients

with superior products that define the forefront of innovation in the diesel engine technology landscape.

At Elkoso, precision manufacturing is at the core of our commitment to excellence, and this is particularly evident in our production of nozzles and nuts for common rail injectors.

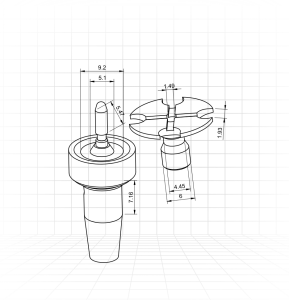

Injector Parts

Technical Specifications

- Dimensions and Tolerances:

- Orifice Diameter: Typically ranges from 100 to 200 micrometers, with tolerances in the range of a few micrometers.

- Nozzle Geometry: The geometry, including the number and shape of orifices, is designed to optimize fuel spray patterns and atomization.

- Performance Requirements:

- Pressure Handling: Nozzles must withstand injection pressures up to 2,500 bar (36,000 psi) or higher.

- Wear Resistance: The materials and coatings must resist wear from high-pressure fuel flow and contaminants.

- Precision Atomization: The nozzle must provide precise fuel atomization to ensure efficient combustion and meet emission standards.

Quality Control and Testing

- Non-Destructive Testing (NDT):

- X-Ray Inspection: Used to detect internal flaws or inconsistencies in the material.

- Optical Inspection: High-resolution cameras and microscopes are used to inspect the surface quality and geometry of the nozzle orifices.

- Dimensional Inspection:

- Coordinate Measuring Machines (CMM): Used for precise measurement of nozzle dimensions and geometries.

- Surface Roughness Testing: Ensures the surface finish meets stringent specifications to prevent fuel flow issues.

- Performance Testing:

- Spray Pattern Analysis: Ensures that the nozzle produces the correct spray pattern for optimal fuel-air mixing.

- Flow Rate Testing: Verifies that the nozzle allows the correct amount of fuel to flow through under specified conditions.

- Durability Testing: Includes cyclic loading tests to simulate long-term operation and ensure the nozzle can withstand prolonged use.

By utilizing high-quality materials, advanced manufacturing processes, and rigorous quality control, ELKOSO ensures that its common rail injector nozzles meet the demanding requirements of modern diesel engines, providing reliable and efficient fuel injection to optimize performance and minimize emissions.