Componentes de fabricación premium

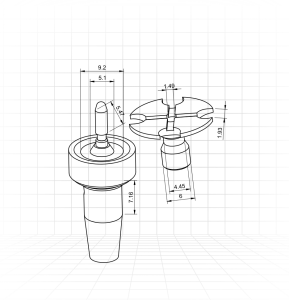

Ejes de bomba CR

En ELKOSO estamos orgullosos de nuestro compromiso inquebrantable con la fabricación de ejes de bombas de la más alta calidad.

Our pump shafts are crafted from carefully selected, top-grade materials, ensuring superior strength, durability, and resistance to corrosion.

Our team of skilled engineers employs cutting-edge design principles to create pump shafts that optimize performance,

taking into account precise specifications and operating conditions.

Our commitment to quality is unwavering, with comprehensive quality control measures at every stage of production.

Non-destructive testing methods are employed to identify and eliminate any potential defects.

Our pump shafts are crafted from carefully selected, top-grade materials, ensuring superior strength, durability, and resistance to corrosion.

Our team of skilled engineers employs cutting-edge design principles to create pump shafts that optimize performance,

taking into account precise specifications and operating conditions.

Our commitment to quality is unwavering, with comprehensive quality control measures at every stage of production.

Non-destructive testing methods are employed to identify and eliminate any potential defects.

En ELKOSO nos enorgullecemos de nuestro compromiso inquebrantable con la fabricación Ejes de bomba de la más alta calidad. Nuestros Los ejes de las bombas están fabricados con cuidado Materiales seleccionados de primera calidad, garantizando superior strength, durability, and resistance to corrosion.

Información técnica

Información adicional

Información técnica

Ejes de bomba CR

Especificaciones técnicas

- Dimensiones y tolerancias:

- Diámetro y longitud: Las dimensiones exactas varían según el motor específico y el diseño de la bomba, pero normalmente varían desde unos pocos milímetros hasta varios centímetros de diámetro.

- Tolerancias: Las tolerancias dimensionales estrictas (en el rango de micrómetros) son cruciales para el funcionamiento correcto y el ajuste dentro del conjunto de la bomba.

- Requisitos de desempeño:

- Resistencia y durabilidad: El eje debe soportar altas cargas cíclicas y presiones típicas de los sistemas common rail.

- Resistencia a la corrosión: Los materiales y tratamientos de superficie deben resistir la corrosión provocada por el combustible y la exposición al medio ambiente.

- Precisión: Es necesaria una alta precisión en la geometría del eje para garantizar una interacción adecuada con otros componentes de la bomba y un suministro constante de combustible.

Control de calidad y pruebas

- Ensayos no destructivos (END):

- Prueba ultrasónica: se utiliza para detectar fallas internas o inconsistencias en el material.

- Inspección de partículas magnéticas: Ayuda a identificar defectos superficiales y cercanos a la superficie.

- Inspección dimensional:

- Máquinas de medición por coordenadas (CMM): se utilizan para la medición precisa de dimensiones y geometrías.

- Prueba de rugosidad superficial: Ensures the surface finish meets specifications.

- Pruebas de rendimiento:

- Prueba de fatiga: Evalúa la durabilidad bajo condiciones de carga cíclica.

- Pruebas de presión: Verifica que el eje pueda soportar las presiones operativas sin deformarse ni fallarse.

Al combinar materiales de alta calidad, procesos de fabricación avanzados y pruebas rigurosas, ELKOSO garantiza que sus ejes de bomba de riel común cumplan con los exigentes requisitos de los motores diésel modernos.

Información adicional