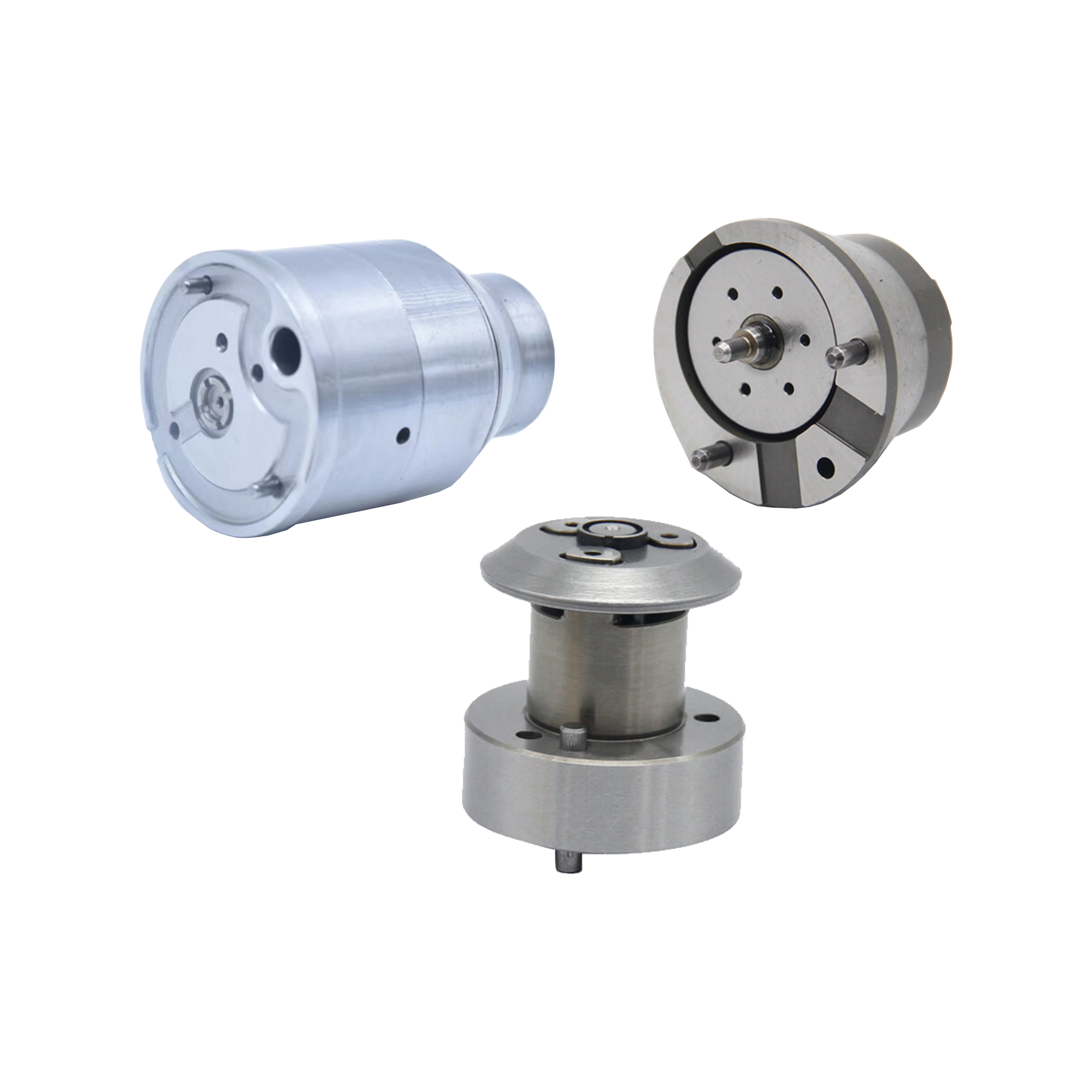

Producing heavy-duty injector spare parts involves specialized manufacturing processes and

materials to meet the high demands of heavy machinery, construction equipment, and large diesel engines.

ELKOSO, as a manufacturer, ensures that these parts offer durability, precision, and reliability.

ELKOSO takes pride in offering a comprehensive range of turbochargers, with a focus on quality craftsmanship and cutting-edge technology, OEM ELKOSO’s turbochargers are meticulously engineered to deliver exceptional power.

Heavy Duty Parts

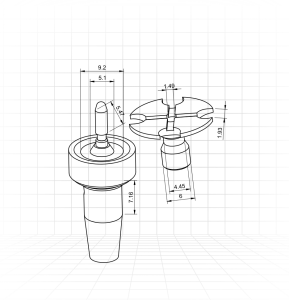

Technical Specifications

- Injector Nozzles:

- Manufacturing: Precision-drilled using laser or EDM techniques for accurate fuel atomization.

- Material: High-strength steel alloys with DLC or CrN coatings for wear resistance.

- Plungers and Barrels:

- Manufacturing: Precision-machined and heat-treated for high-pressure tolerance and durability.

- Material: Tool steels with advanced surface treatments to reduce friction and wear.

- Needle Valves:

- Manufacturing: Micro-machined for precise control over fuel injection.

- Material: High-strength stainless steel or special alloys with surface coatings.

- Control Valves:

- Manufacturing: CNC-machined for tight tolerances and reliable performance.

- Material: High-performance alloys and composites for durability under high pressures.

- Dimensions and Tolerances:

- Orifice Diameter: Nozzle orifice diameters typically range from 100 to 200 micrometers, with tolerances within a few micrometers.

- Critical Dimensions: Components such as plungers and needles require extremely precise geometries to ensure proper sealing and fuel delivery.

Quality Control and Testing

- Non-Destructive Testing (NDT):

- Ultrasonic Testing: Detects internal flaws in materials.

- Magnetic Particle Inspection: Identifies surface and subsurface defects.

- X-Ray Inspection: Used for detailed internal examination of parts like nozzles and plungers.

- Dimensional Inspection:

- Coordinate Measuring Machines (CMM): Ensure dimensional accuracy and compliance with design specifications.

- Surface Roughness Testing: Verifies that surface finishes meet required standards.

- Performance Testing:

- Spray Pattern Analysis: Ensures correct spray pattern for optimal fuel-air mixing.

- Flow Rate Testing: Verifies correct fuel delivery.

- Durability Testing: Simulates long-term operation to ensure components can withstand prolonged use.

By leveraging high-quality materials, advanced manufacturing processes, and rigorous quality control, ELKOSO ensures that its heavy-duty injector spare parts meet the demanding requirements of industrial applications, providing reliable performance and longevity in harsh operating environments.